Our Solutions

Discover Mekitec's cutting-edge X-ray inspection systems and software solutions designed for the food industry

X-ray Inspection Systems

Our lineup of advanced X-ray inspection systems for food safety and quality control

MEKI™ ONE

MEKI™ ONE combines superior X-ray sensitivity with a compact design, offering everything needed for a critical control point in one comprehensive package.

All-in-One Solution

Complete quality control station in a single compact package

Automatic Rejection

Integrated rejection system with confirmation capability

Comprehensive Reporting

Advanced reporting system for quality assurance documentation

Cost-Effective

Best price-quality ratio for food production quality control

MEKI™

An automated quality control system that uses advanced X-ray technology to detect foreign objects while ensuring product quality and traceability

Foreign Object Detection

Detects metal, stones, glass, bones, and dense plastics inside food products

Space-Efficient Design

Requires minimal installation space compared to other X-ray systems

Quality Assurance

Ensures overall quality and traceability of food production

Versatile Inspection

Effective regardless of moisture, salt content, or packaging materials

MIDMEKI

MIDMEKI offers superior quality control for medium-sized and multi-pack food products using cutting-edge X-ray technology that delivers precision detection without packaging limitations.

Enhanced Detection Area

Wider conveyor and larger detection zone accommodates medium-sized products and multi-pack trays

Material Versatility

Effectively inspects products regardless of moisture, salt content, or packaging material including metal and aluminum

Primary Packaging Focus

Specialized for inspection at the primary packaging stage for optimal performance and value

Advanced X-ray Technology

Utilizes latest X-ray image processing technology for superior foreign object detection

SIDEMEKI™

Advanced X-ray quality control solution designed specifically for tall packages in both liquid and solid food production lines.

Two X-ray Configuration

Optional one or two X-ray generators tailored to your specific inspection requirements

Tall Package Optimization

Specialized design for bottles, cartons, containers and cans where height exceeds width

Pack-by-Pack Traceability

Complete traceability system ensuring quality control for each individual package

Production Flow Integration

Engineered for seamless integration without disrupting production line efficiency

WIDEMEKI

WIDEMEKI X-ray inspection system is designed for food packages that are significantly wider than standard consumer packaged food products, providing automated X-ray inspection at the best value in the industry.

Dual X-Ray Technology

Two parallel and partly overlapping X-ray images from separate generator and detector pairs

Wide Product Capability

Designed specifically for wide products like pillow pack applications

Energy Efficient

Eliminates need for high-power generator, reduces system size and energy consumption

Superior Detection

Improved image quality and foreign object detection performance

BULK MIDMEKI

The BULK MIDMEKI model extends our trusted technology to bulk food applications, enabling food producers to secure the quality of their raw materials and unpackaged products with exceptional detection accuracy and sensitivity.

Bulk Product Inspection

Specifically designed for unpackaged bulk products like nuts, dried fruits, seeds, and vegetables

High Capacity Processing

Conveyor load capacity up to 20,000 kg/h for industrial production

Customizable Integration

Product feed and handling can be tailored to fit your production process

Reliable Detection

Advanced X-ray imaging technology with practical design for consistent performance

HIGHER MIDMEKI

Building on the classic MIDMEKI system, the 500W version expands its capabilities with a more powerful generator and a wider detection area, designed to inspect thick and dense products with outstanding image clarity.

High-Power Generator

More powerful 500W generator for inspecting thick and dense products

Wide Detection Area

Expanded detection area for large products like cheese wheels and butter blocks

Outstanding Image Clarity

Superior image quality makes it easier to detect even the smallest anomalies

Versatile Applications

Ideal for wide or dense products, trays, and secondary packaging like boxes or multipacks

BIGMEKI

BIGMEKI quality control system leverages the latest X-ray image processing technology and artificial intelligence algorithms, combining the strengths of MIDMEKI system with substantially larger detection area for inspecting larger packages and secondary packaging.

AI-Powered Technology

Latest X-ray image processing technology with artificial intelligence algorithms

Large Detection Area

Substantially larger detection area ideal for oversized primary and secondary packaging

Flexible Configuration

Two conveyor speed and load capacity options to match production requirements

Material Versatility

Handles high moisture, elevated salt levels, and various packaging materials including metal and aluminum

Inspection Software Solutions

Powerful software tools to enhance your inspection capabilities and data management

MEKI Assurance Intelligence

Advanced X-ray inspection software that transforms food safety with artificial intelligence, providing superior contaminant detection and operational efficiency.

Enhanced Detection Capability

Up to 15% improvement in identifying low-density foreign objects

Reduced False Rejections

Decrease unnecessary product waste by up to 20% without compromising safety

Digital Validation

Paperless CCP validation tests performed directly within the inspection system

Automated Reporting

Seamless integration with MEKI Data Manager for effortless compliance documentation

MEKI Data Manager

Advanced solution for collecting, analyzing, and leveraging X-ray inspection data to optimize food production quality, safety, and traceability.

Comprehensive Data Analytics

Access and analyze vital production metrics including rejection rates, timestamps, and X-ray images

Enhanced Food Traceability

Time-stamped X-ray images enable precise product tracking and targeted recall capabilities

Audit-Ready Reporting

Quickly gather CCP data and generate comprehensive reports for regulatory compliance

False Reject Prevention

Identify patterns in rejection data to optimize inspection parameters and reduce waste

Key Applications

Discover how our X-ray inspection systems solve real-world challenges across various industries

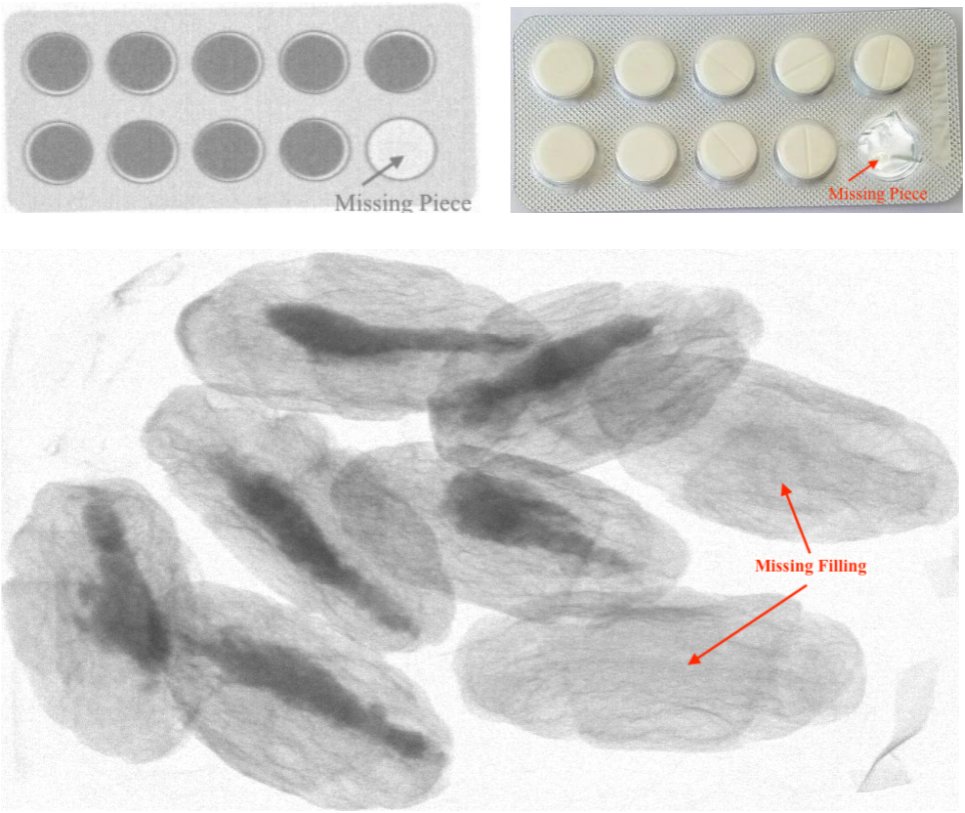

Counter & Filling Inspection

Confirm every pack has the right number of pieces and fillings, even when pieces overlap

How it Works

Set the expected piece count and filling targets. The X-ray image is analyzed to find pieces and filling areas; the system measures density in each area and estimates how many pieces belong to it. Smart separation tools split touching or horizontally joined pieces, then results are checked against limits for pass or reject. Auto-calibration keeps performance stable, similar to Foreign Object Detection.

Key Benefits

- Accurate counts and filling verification, even with overlapping pieces

- Fewer complaints and giveaways by rejecting only off-count packs

- Consistent quality that protects brand trust

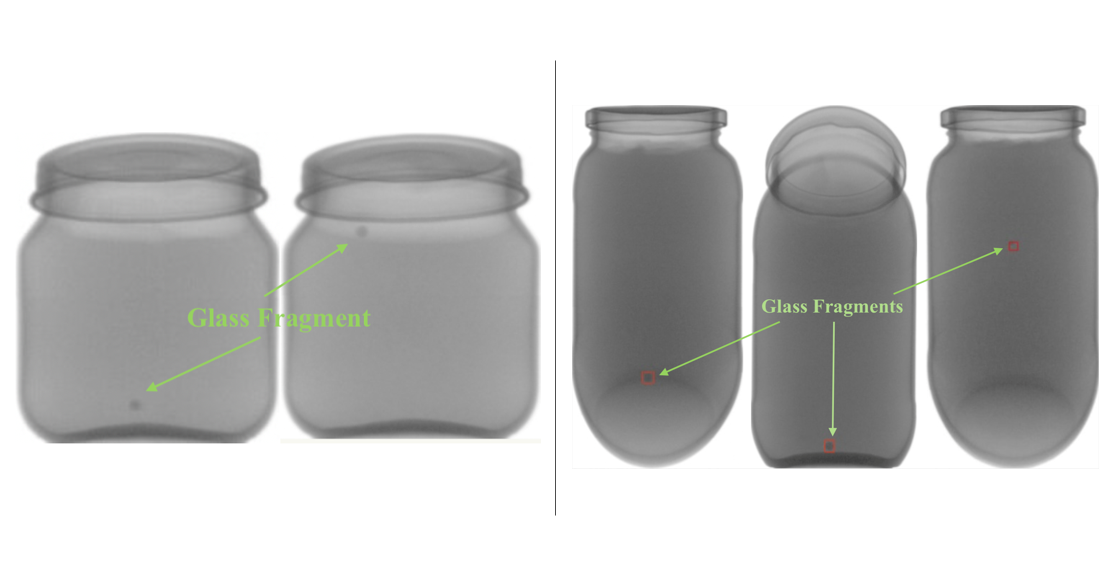

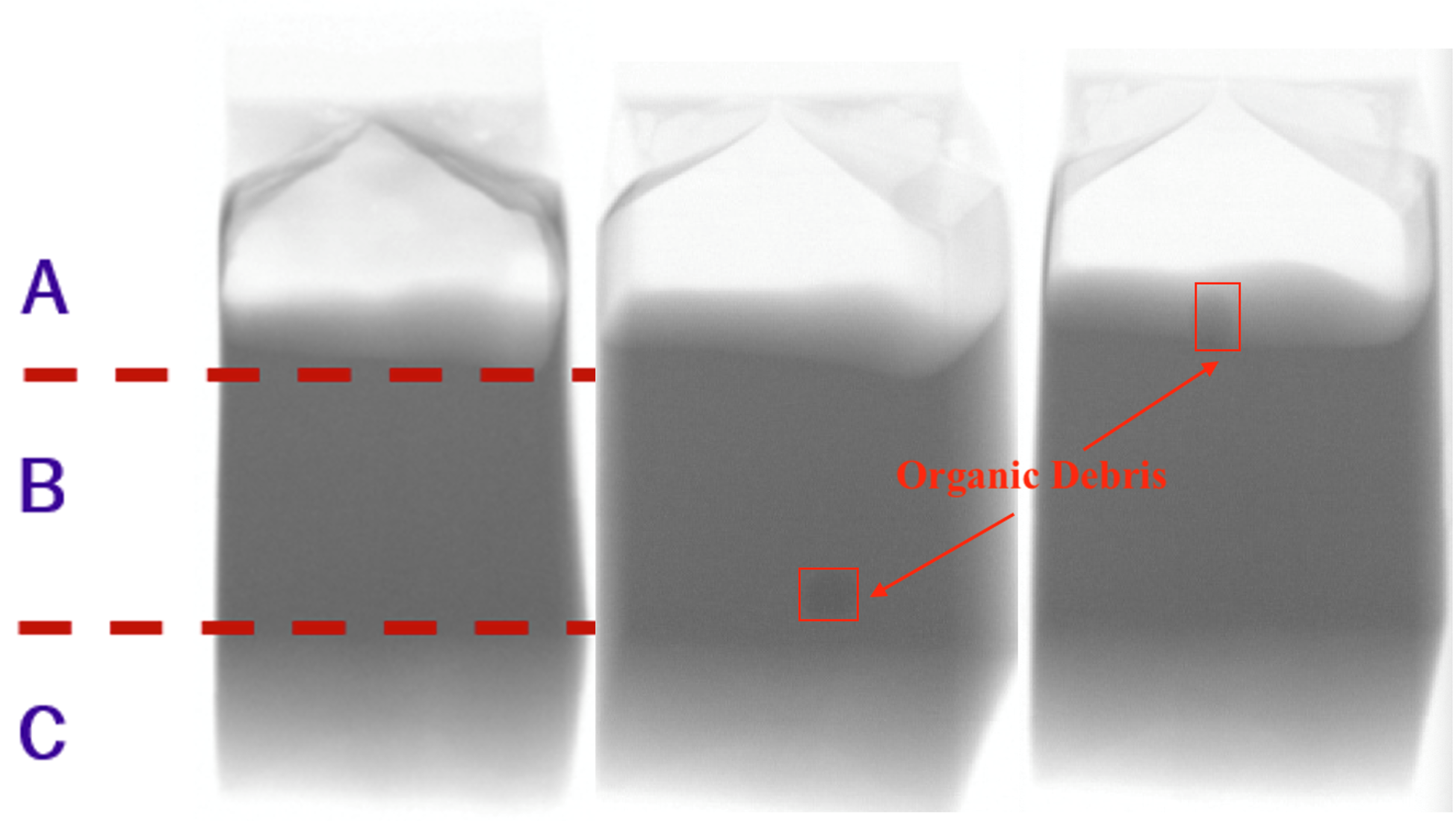

FO Detection in High-Density Containers

Detect foreign objects in hard-to-reach areas within high-density containers

How it Works

MEKI AI makes it possible to detect foreign objects even in challenging, dense products or packaging. By adapting how the system inspects different areas, it significantly improves detection accuracy where it's traditionally most difficult. The capability is most useful for SIDEMEKI applications.

Key Benefits

- Improved detection in challenging high-density containers

- Improved detection in challenging areas

- Clear visual segmentation

- Tailored algorithm selection

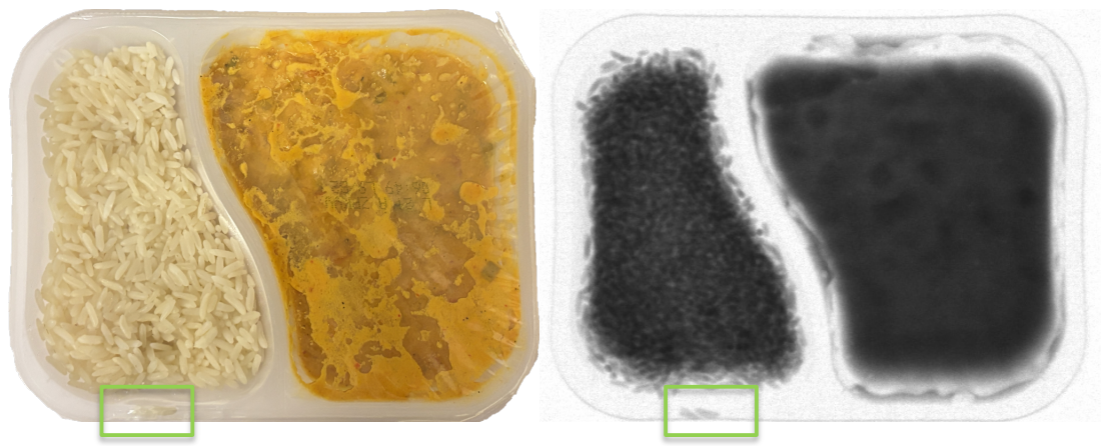

Seal Inspection

Prevent food or product spoilage by rejecting products with faulty seals

How it Works

The system detects broken or open seals by scanning the sealed area of each package. It flags seals that trap product material, often a sign of leakage or contamination. It works reliably across all packaging types and sealing methods.

Key Benefits

- Ensures seal integrity

- Prevents leaks and spoilage

- Adapts to all product shapes and sizes

Glass detection in glass containers

Detect foreign objects especially glass within a glass container

How it Works

The glass container is divided into multiple zones, e.g. high- and low-density zones. Users customize detection settings specifically for glass detection, leveraging both classic imaging techniques and advanced AI models. Configuration options and color overlays enable detection within different density areas.

Key Benefits

- Improved detection in hard-to-see zones

- Clear, color-coded visual segmentation

- Size of foreign object detection starts from 2mm for Glass contaminant in a Glass container

Detection of organic material

X-ray technology that detects organic debris like fruit pits in food products by analyzing density differences, ensuring accurate quality control with minimal false positives

How it Works

An X-ray image is analyzed to identify organic debris within the filling zones. The system measures density gradients within each area, differentiates debris from the product and flags them. Results are evaluated against predefined accept and reject thresholds. Auto-calibration maintains consistent performance over time, similar to Foreign Object Detection.

Key Benefits

- Accurate detection of small organic debris in low-viscosity food products

- Optimized quality control, rejecting only products containing organic debris, reducing false positives, customer complaints, and waste

- Consistent product quality that enhances brand reputation

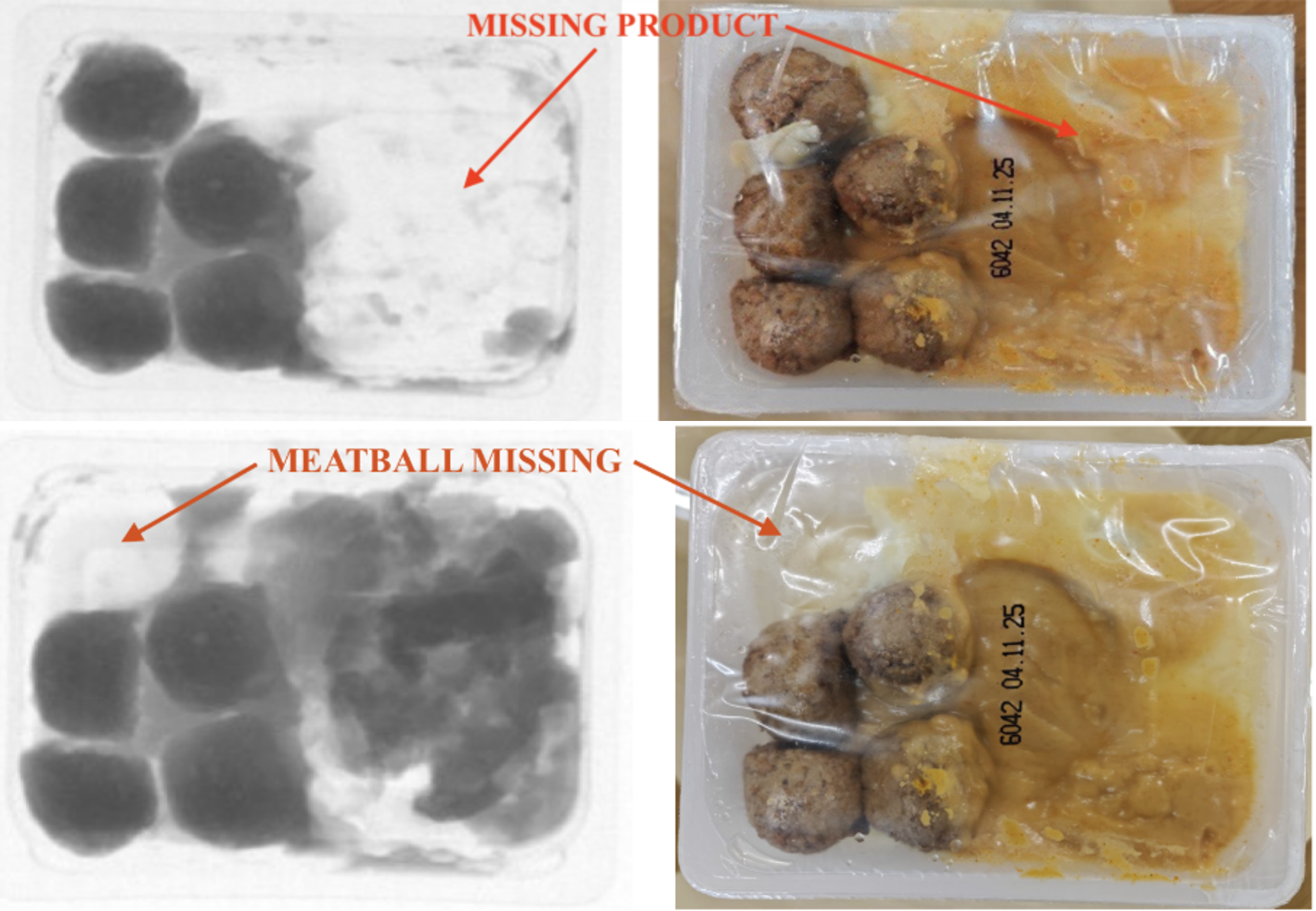

Missing product detection in food packaging

X-ray-based system that detects missing or excess product in food packaging through precise density analysis, ensuring quality control and reducing waste

How it Works

The system checks overall product density from X-ray images to detect under- or over-filled packages. It also divides the image into a grid, calculates density and area percentages for each cell, and compares them to user-set thresholds. If enough cells meet criteria, the package is accepted; if not, it’s marked as not OK.

Key Benefits

- Reliable detection of under- or over-filled product in food packages

- Enhanced quality control with precise density evaluation, reducing under- or over-filled errors that lead to customer complaints, negative online feedback, and unnecessary product waste

- Ensures consistent detection performance over time, strengthening product quality, reinforcing brand trust, and improving consumer confidence

Request a Custom Quote

Contact our sales team to discuss your specific inspection needs and get a personalized quote.

Contact Us